In the world of textiles, whether you’re in fashion design, upholstery, or the garment industry, efficiency and precision are key. That’s where Fabric cutting machine and pattern design software come into play. These tools are not just for professionals—they are transforming how everyone from large factories to individual crafters approach their projects. But what exactly are these technologies, and how can they help you? Let’s dive into the details.

What is a Fabric Cutting Machine?

Overview of Fabric Cutting Machines

A fabric cutting machine is a device designed to precisely cut fabrics into shapes, patterns, and designs. Unlike manual cutting methods that require scissors or rotary cutters, these machines use high-speed blades, lasers, or knives to cut fabric quickly and accurately. They are used in industries such as fashion, automotive, and home decor, where fabric needs to be cut into consistent sizes and shapes.

Types of Fabric Cutting Machines

Fabric cutting machines come in various types, each suited for different kinds of tasks. Here are a few popular ones:

- Manual Cutting Machines: These are typically more affordable and are ideal for smaller scale operations.

- Automated Cutting Machines: These machines are designed for high-volume production and offer advanced features like programmable settings and precise cutting.

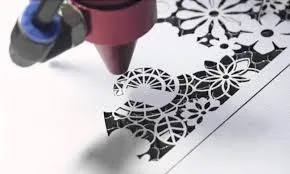

- Laser Cutting Machines: These machines use high-powered lasers to cut fabric with extreme precision, making them ideal for intricate designs.

- Plotter Cutting Machines: Often used for cutting patterns from sheets of fabric, these machines are controlled by computer software for accurate, repeatable cuts.

The Role of Pattern Design Software

What is Pattern Design Software?

Pattern design software allows designers to create, modify, and optimize patterns for fabric cutting. With advanced features, designers can create complex patterns, experiment with colors and styles, and visualize how fabrics will look once cut and assembled. The software ensures that patterns are perfectly suited to fabric shapes, grain lines, and other critical elements.

Benefits of Using Pattern Design Software

- Accuracy: Pattern design software helps ensure that the design fits perfectly, minimizing material waste.

- Speed: With the ability to quickly generate patterns, designers save time and can experiment with different designs without needing to start from scratch.

- Customization: Users can easily modify and adjust patterns to meet specific needs, whether it’s for a one-of-a-kind piece or large-scale production.

How It Enhances Fabric Cutting Machines

When combined with a fabric cutting machine, pattern design software allows for seamless integration, ensuring that the patterns created are automatically fed into the machine for precise cutting. This eliminates the risk of human error, speeds up the entire production process, and ensures that the cuts are exactly as designed.

How Fabric Cutting Machines and Pattern Design Software Work Together

Seamless Integration for Precision and Efficiency

Imagine you’re designing a collection of custom apparel, and you’ve just spent hours perfecting the patterns using your pattern design software. With a fabric cutting machine linked directly to your software, the patterns can be fed into the machine automatically. No need to manually transfer measurements or trace designs. The machine takes over, cutting your fabric precisely as needed, in record time. This integration enhances both precision and efficiency, freeing you up to focus on the creative side of your work.

Case Studies of Successful Integration

Several large manufacturers in the fashion and automotive industries have already integrated fabric cutting machines with pattern design software to streamline their production processes. Companies like Gerber Technology and Lectra have developed solutions that allow for the precise cutting of materials for fashion, upholstery, and even car interiors. These tools not only enhance accuracy but also help businesses reduce material waste, lower production costs, and speed up turnaround times.

Choosing the Right Fabric Cutting Machine and Software

Key Features to Look for in Fabric Cutting Machines

When selecting a fabric cutting machine, it’s crucial to look for features that will meet your specific needs. Here are a few things to consider:

- Cutting Speed: Faster machines can increase overall productivity.

- Cutting Precision: Look for machines that offer detailed, clean cuts.

- Material Compatibility: Choose machines that can handle a wide variety of fabrics.

- Ease of Use: The interface should be user-friendly, especially if you’re new to fabric cutting technology.

Top Pattern Design Software for Fabric Cutting

Not all pattern design software is created equal. Some popular options in the industry include:

- Optitex: Known for its 3D simulation capabilities, making it perfect for fashion designers.

- TUKAcad: A great tool for pattern creation and marker making, ideal for high-efficiency workflows.

- Gerber Accumark: Widely used in both garment and industrial design, known for its robust features.

The Benefits of Investing in Fabric Cutting Machines and Pattern Design Software

Increased Efficiency and Speed

By automating the cutting process and integrating it with pattern design software, fabric cutting machines significantly speed up the production timeline. What would typically take hours or even days can now be done in a fraction of the time, allowing you to scale your operation or focus on other critical tasks.

Cost Savings Over Time

While the initial investment in these technologies might seem substantial, they pay for themselves in the long run. Reduced material waste, fewer errors, and faster production times all lead to lower costs over time.

Conclusion

Fabric cutting machines and pattern design software are revolutionizing how the textile industry operates. These tools not only enhance precision and efficiency but also enable designers and manufacturers to produce high-quality items at a faster rate and lower cost. Whether you’re a small business owner or a large manufacturer, investing in these technologies can lead to greater productivity and a more streamlined workflow.

FAQs

1. Can fabric cutting machines handle all types of fabrics?

Yes, most modern fabric cutting machines can handle a wide range of fabrics, from cotton and wool to synthetics and leather. However, it’s important to check the machine’s specifications to ensure compatibility.

2. How does pattern design software improve design accuracy?

Pattern design software allows for precise measurements, automatic scaling, and real-time adjustments, which significantly reduce human error and enhance the overall accuracy of the patterns.

3. Are fabric cutting machines difficult to operate?

No, many fabric cutting machines are designed to be user-friendly. With training and practice, even beginners can operate them effectively.

4. Can I use my pattern design software with any fabric cutting machine?

Not all software is compatible with every fabric cutting machine. It’s crucial to choose a software and machine combination that works well together, often from the same manufacturer.

5. How long does it take to learn to use fabric cutting machines and pattern design software?

The learning curve varies depending on the complexity of the machine and software, but with proper training, most users can become proficient within a few weeks.